Last week I was busy making clay for the fast approaching, up-coming weekend workshops. I made half a tonne of special clay body with a bit of extra grit, adding some more ‘tooth’ to the usual reliable body that I make up for us.

It took me two days. I can make up a quarter of a tonne of clay each day from scratch, pug it twice to ensure even mixing, then re-pugged through the Venco Vacuum pug mill and finally bagged and stacked. Along with sorting materials, weighing out, mixing, pugging and finally cleaning up, I have to have a day off in-between to catch up and to avoid over-doing it. Suddenly a week has gone by, but now it’s all done and ready for the next couple of workshops. We are pretty self reliant in the pottery here. Using our own electricity, our own rain water, using all the machinery and equipment that I have either made, re-purposed or re-built after the fire. I’m fairly proud of this minor achievement of self-sufficiency.

This week we have been very busy with all sorts of little jobs. We ate the last of our late season tomatoes. Surely this must be the last of the late crop. I’m not expecting the last 3 green toms to ripen very well, so these half dozen little self sown gems will probably be it. And very nice too. We cant expect to see another ripe tomato here until just before Xmas if all goes well with the spring planting for next summer’s crop. This must be some sort of record for us, eating home grown red ripe tomatoes for the garden in the last week of July.

What we are getting a lot of from the garden are cauliflowers, broccoli and Brussels sprouts, all the usual winter fare. last night I harvested the first pick of parsnips for our baked veggie dinner. Cauliflowers, broccoli, Brussels sprouts, parsnips, potato, pumpkin and onion, baked in the oven and then dressed in a cheesy béchamel source. A lovely, warming, winters dinner.

This weeks loaf of rye bread was the usual beauty. All crusty and solid dense rye inside. I use 50% of wheat flour as well so as the get it to rise, as there is very little gluten in rye flour, but it has fantastic flavour. I’m using locally grown and milled organic stone ground flours from the wheat belt of NSW. All grown, harvested and milled on site on the family farm.

This week we also hosted a weekend workshop, but held mid-week, Tuesday to Thursday for a student from FNQ. I had offered a glaze workshop last year, but only got 3 replies, and only one who paid. so it was cancelled. Not enough to make it worthwhile to run it. One potter enquired as to when the next one would be offered. I told her that it wouldn’t. Then she asked how much it would cost for me to do a private one-on-one workshop. She applied for a grant, was successful and so she was here this week. A year later than originally offered.

I spent Tuesday morning waiting for her to arrive from Queensland sieving wood ashes from the various fires, stoves, burn piles and kiln fireboxes, ready for use in our testing. I still had a little time, before she arrived, so decided to make a wooden pottery tool. At the last throwing workshop, my good friend Len Smith left behind a wooden comb that turned up in the throwing water. I really liked it and had got used to using it. It’s very comfortable in the hand and very useful. I really like it and was sad to have to give it back when Len next visited for the recent wood firing a week or so back. I decided to make one for myself, so I set to it and in half an hour I had one made. Not as good as Len’s, but I think that it is workable. and most importantly, it’s home made onsite from scrap wood. Not as good as the bought one perhaps, but individual, personal and much more meaningful. It still needs a little bit more sanding and finishing, then some vegetable oil, and it’s ready to go.

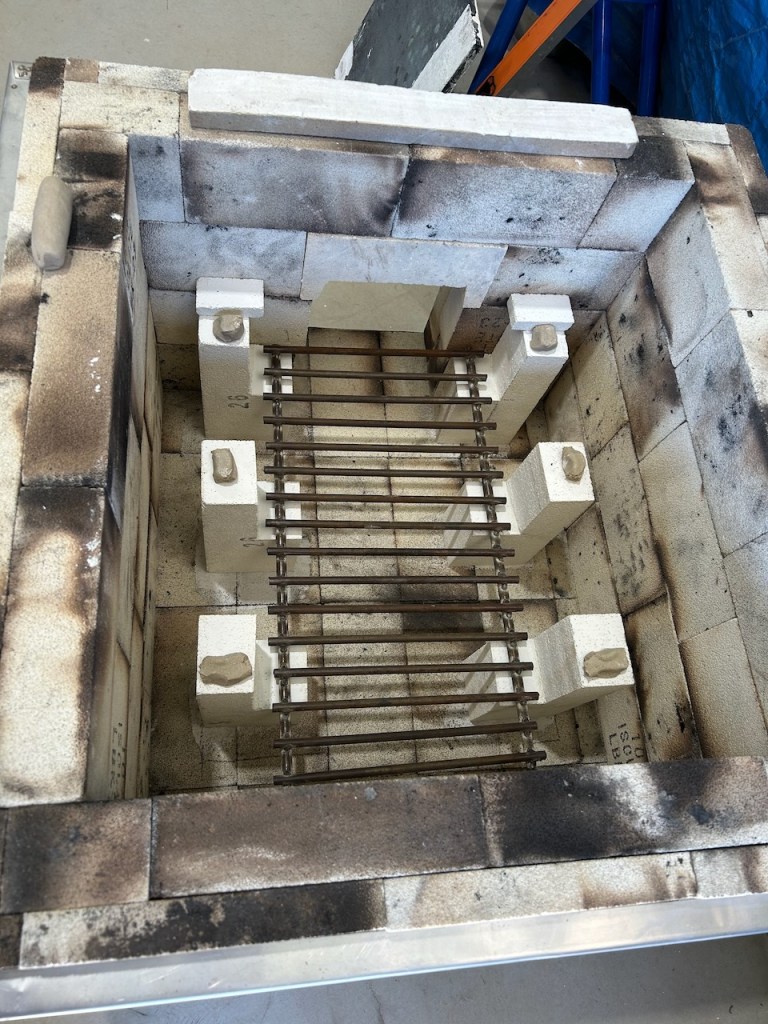

When my student arrived from the airport, we had lunch and spent the afternoon doing a geology tour of the Southern Highlands, collecting samples and talking geology, analysis and geological maps on the short drives in-between sites. Day two was spent crushing and milling our samples in the morning and then making glaze tests in the afternoon. We finished the weighing out in the late afternoon, having completed 13 test tiles, half for oxidation and half destined for reduction firing. We packed both the electric kiln and small gas kiln with our test tiles before dinner. The solar electric kiln was fired over night used the days stored sunlight energy from our battery, while we fired the small portable gas kiln during the evening into the night, a 3 hour reduction firing from 6 till 9.00PM.

Day three morning was spent unpacking the kilns, debriefing on the results, and then a theory class on glaze technology, choice of materials, Segar Formula and loads of other relevant related glaze topics. We finished on que at lunch time, in time for her return to the airport for her flight home. A fully packed, midweek-weekend, intensive crash course in geology, rock glazes and using collected ‘wild’ local materials. Ashes, gravels, arkose, clays and rocks, all alchemically metamorphosed from road side dirt into shiny glazes.

You must be logged in to post a comment.