We live in an age of instant access to information and news, except that it’s all mostly bad. I’ve stopped watching the news. It’s all too depressing. I don’t want to be ‘connected’ to this. I want my interactions to be quiet, peaceful and positive. I want to choose a constructive, creative, engagement with my environment and the people around me.

I have spent my life developing a philosophy of minimal consumption and self-reliance. I believe in not buying anything that I don’t need and not throwing anything away that isn’t fully worn out. This has been part of an exploration of how it might be possible to live frugally and gently in a faster, noisier and bigger world of seemingly senseless and excessive consumerism.

My Partner Janine King and I work in isolation, making only what pleases us. This is not good business practice, but we don’t think of ourselves as being in business. We are trying to live an independent creative life, that is sensitive to our surroundings, gentle on the earth, low-carbon and low-impact on others around us. We are attempting to live this life of small monetary rewards, but high satisfaction and so far it seems to be working out OK for us.

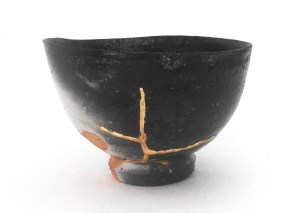

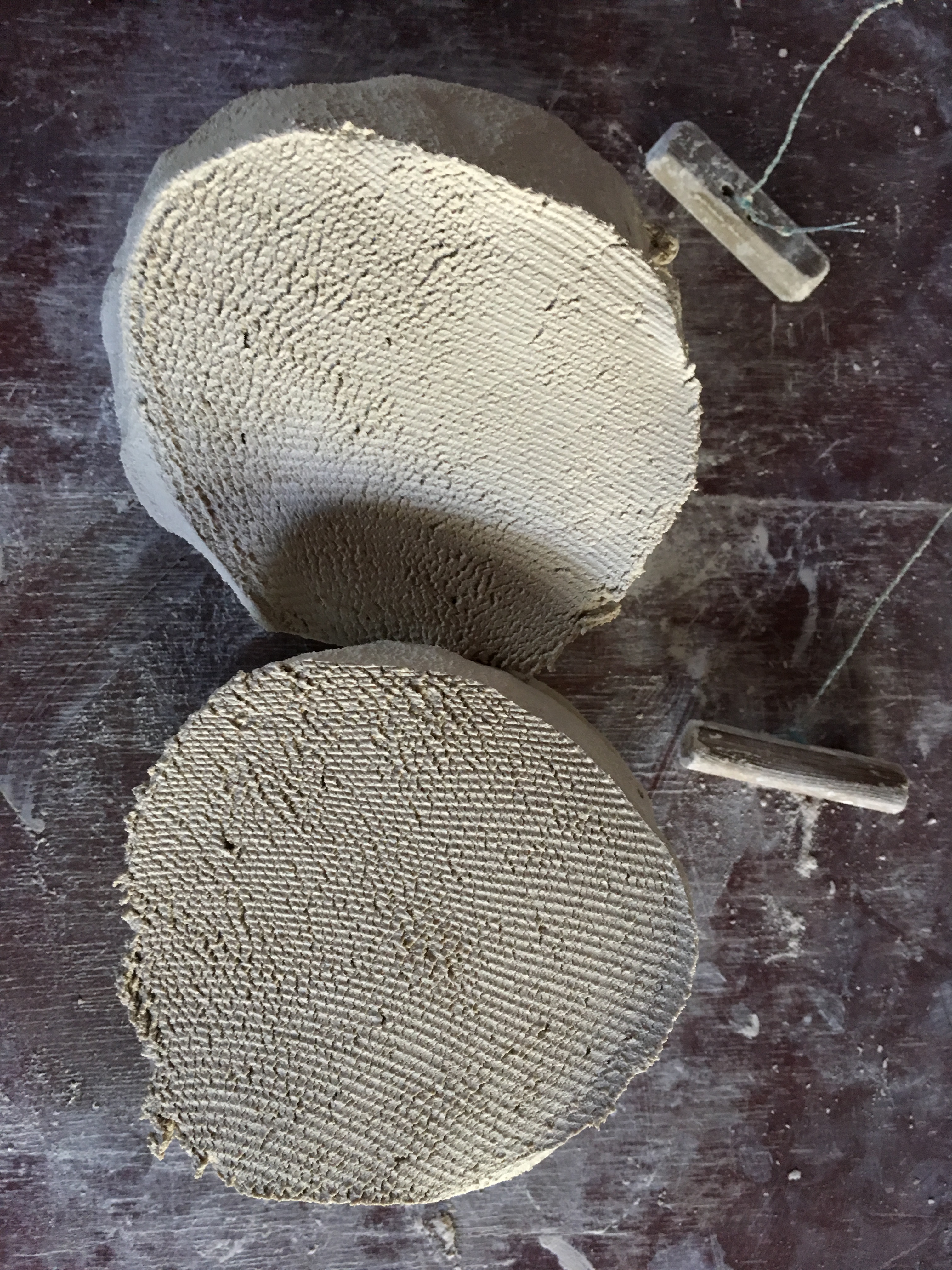

I work with the raw materials that I can find around me in my immediate locality and then research and test them, to attempt to discover what interesting qualities they exhibit and then try to make original ‘location-specific’ works from them. I find this approach most fascinating and very rewarding. I have discovered a single-stone native porcelain, and developed a body from it that is very beautiful, especially when wood fired. I have also found and developed a single-stone, washed basalt gravel, blackware body that is gorgeous. These two special materials are the result of a lifetimes research. Not much to show for a life, but I continue to create these Senseless Acts of Beauty, because it pleases me. I am under no illusions. I know that I could not have lived this quality of life without Janine as my partner to help me achieve it, but most importantly, we have been very lucky to have lived this simple, artistic life in Australia, where there has been no civil unrest.

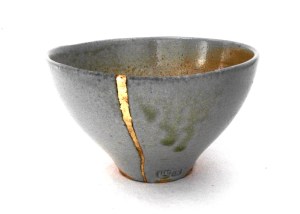

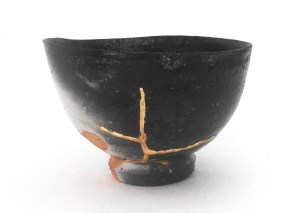

It has been my intension during my career to make simple, elegant, and hopefully beautiful bowls. These bowls have been significantly influenced by Japanese and Chinese aesthetics as well as the Japanese culture of tea and Zen Buddhism I’m not a Buddhist. But some of the thinking around Zen practice has influenced my quest to live a simple, non-consumerist, low-carbon life. When I was studying the origins of single-stone porcelain in Japan recently. I did a course in Kintsugi. The Japanese art of repairing broken pottery with lacquer and pure gold. I have started to repair some of my more interesting failures using this technique.

Kintsugi embodies three Buddhist concepts and makes them tangible. The first is ‘wabi-sabi’. Realising that something that is flawed and imperfect can still be extraordinarily beautiful The second is ‘mushin’, the concept of non-attachment and acceptance of change. Nothing is perfect, nothing lasts and nothing is ever finished. The last is ‘mono no aware’, a certain wistfulness at the impermanence of things. We are only here for such a short time together. Our transience is a reality of our life. Embrace the moment as it is.

I feel that when I repair a beautiful pot that is broken, damaged or otherwise ‘non-perfect’ in a Western, conservative sense, I make it all the more beautiful. Spending time recovering and enhancing something that is otherwise lost, is a sign of great respect for that object. It fits well with my philosophy of minimal-consumption, self-reliance and making things last as long as possible.

Because kintsugi has been called the art of embracing damage, it occurred to me that these, recovered bowls might be a suitable and beautiful metaphor for recovery from conflict. Hence my offering them for inclusion in this up-coming end-of-year show at Watters Gallery called ‘war’.

I have very few ambitions in life. When I was young I decided that I would live in the country and to grow my own food, to make a creative life of some sort, build my own house, and live a self-reliant life. I have more-or-less fulfilled all of these modest ambitions. My lasting ambition is to make things that are meaningful, simple and modest. I go about this work of creating random acts of beauty without any regard to the effect that it may have on others. I am selfish, but not thoughtless.

Our indigenous peoples have a long tradition of respectful collecting, gathering and hunting. I feel that my small experiments interacting with the natural world, collecting stones to grind up to make my pots are compatible as a contemporary continuation/interpretation of this ancient practice. It respects place and biota. It’s 40 years since I moved to this small Village in the Southern Highlands south of Sydney. I’m pretty self-contained here. I don’t want for a lot, so I have everything that I need and I am grateful for that.

My bowls are small, simple gestures. They appear to be empty, but are in fact full of good wishes and calm, thoughtful intent.

The exhibition ‘War’ at Watters Gallery opens on Wednesday 23rd of November.

You must be logged in to post a comment.