We fired the big wood kiln last weekend, then during the week, Janine packed and fired the little portable wood fired kiln.

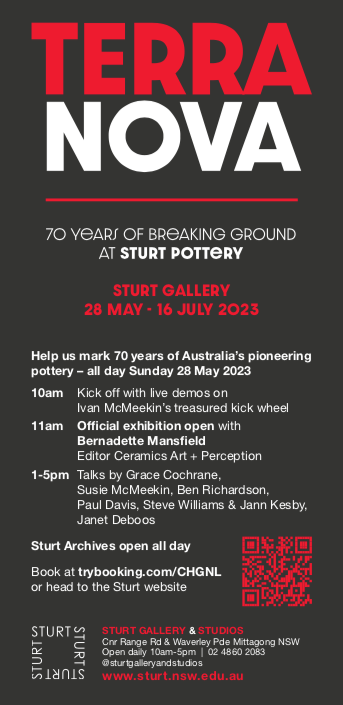

We have put the Sturt ’Terra Nova’ show up and it is going well, with a big turn up at the opening. We got to catch up with loads of people that we only usually see at conferences, and as I don’t go to a lot of conferences, nor do I go to ‘openings’ to do ‘networking’. Well, I don’t get to catch up like this very often. It was really good.

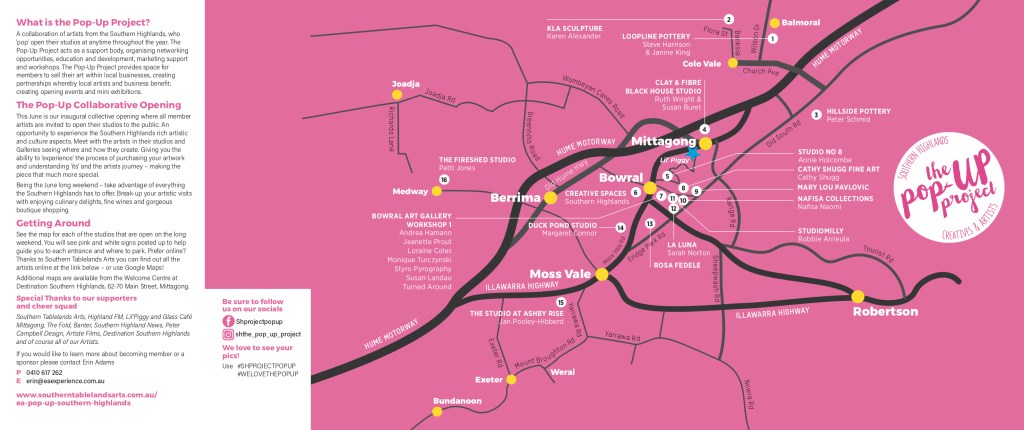

Our next big event on the horizon is the ‘Pop-Up’ Artists Open Studios Arts Trail, that will be on the long weekend of the 10th, 11th, and 12th of June. Hence the flurry of firing activity now in preparation. We have been making all year, and firing in the smaller kilns, the solar PV fired electric kilns. We don’t fire the wood kilns over the hotter part of the year, and certainly not during the fire-ban season. So it’s all go now.

Using a combination of elm garden prunings and some thinly split eucalypt (many thanks to our friends, Susan and Dev, who helped split a lot of side stoking wood with us a month or so ago.) Janine was able to fire up to Stoneware in reduction in 4 1/2 hours. A perfect firing for a little portable kiln.

At the end of the firing, Edna the chicken came to check it out. Janine and Edna had a little chat, cooing and clucking together. The gist of it was probably around the matter of if there was anything for a chicken to eat?

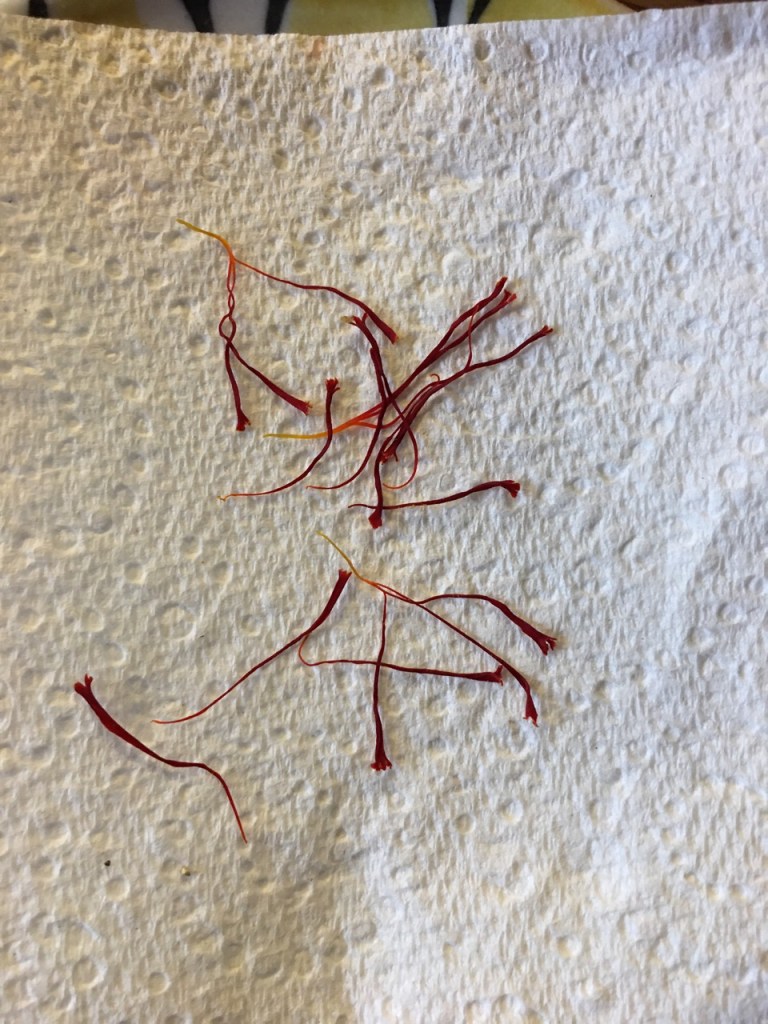

I have been packing the big wood kiln again for another firing this coming weekend. The slowest part of packing the big wood kiln is rolling out all the thousand little clay balls of wadding. Each pot has to sit on a ring of little balls of refractory wadding to stop it sticking to the kiln shelf. Over time, and many, many, firings the kiln shelves get a coating of molten fly ash from the burning wood, and if the pots aren’t held up off the shelf, they will fuse together at high temperature becoming a monolithic whole.

First chamber finished and clammed up.

I think that I probably spend a quarter of my time rolling out these little balls, only to throw them away after the firing. Actually, Janine re-uses them as aggregate in the bottom of planter pots around the garden. However, when we first set out on this creative journey, back in the early ’70’s, because we had very little money and couldn’t afford to buy the very expensive kiln shelves that we needed to pack the big wood kiln. As a work-around solution, we decided to make our own. This was a very tricky bit of ceramic chemistry, and only one other husband and wife couple of potters, Harry and May Davis in New Zealand were doing it. We went to work with them to get some insights, and came back and made our own kiln shelves for next to nothing in terms of cash outlay, but a lot of time invested.

The cost of the high alumina grog used to make refractories was prohibitive, so we made our own. For every firing in the little test kiln that we had, I used very high quality, high alumina kaolin from Mudgee. Puggoon 157 kaolin, purchased directly from the mine not too far away, to make the wadding balls. After firing, instead of throwing them out. I put them through the rock crusher and turned them into high alumina crushed grog. All the failed experimental kiln shelves were also put back through the crusher, mixed with more kaolin 50/50 and used again. Eventually we had enough kiln furniture to fire the big 300 cu. Ft. wood kiln at next to no cost. They weren’t very good, but just good enough and this exercise in self reliance got us going. We still have them, but they are rarely used these days, because the new silicon carbide kiln shelves from China are both affordable and excellent quality.

Photos of me, as a much younger man, making kiln shelves, taken by Janine King

You must be logged in to post a comment.