Building my kiln went pretty easily.

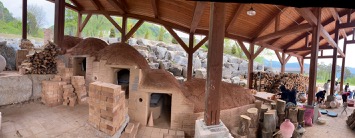

Because the kiln shed wasn’t finished on time, the team of 8 professional kiln builders that are contracted to build the massive North Korean designed 5 chamber kiln that is going in the new shed next to mine, are all sitting with nothing to do for a couple of days, as the slab for their kiln hasn’t even been cast yet. The slab for my kiln was cast the day before I arrived, but as they were still finishing the roof of the shed I wasn’t allowed on site because of the danger of falling objects. So nothing happened for the first day for any of us. We all went into the nearest big town half an hour away to buy groceries for the coming week.

There is almost nothing fresh available here in this little village. There is a junk food ‘convenience store’ that mostly sells soft-drinks, tinned coffee, beer and cigarettes, and a very small ’supermarket’ where you can drop off the first word and buy dried and canned foods that aren’t particularly super in degree or range.

No one sells fresh vegetables, and understandably so, as everyone here, with exception of the dozen museum staff and research students, is involved in farming vegetables. I suppose that they either grow what they need themselves, or swap with neighbours who do. Either way there is nothing fresh in the two tiny shops here.

In the bigger nearby town of Yanggu, there is a choice of bigger grocery shops and one real supermarket. We travel there and get a weeks supply of almost everything that we can think of, that we might need to feed ourselves for the coming week. We spend about $700 on these 3 trolleys of various food items. It even includes shoju and beer! I notice that they sell red wine in there. So return by myself while the others are loading the cars, and buy 4 bottles of red wine, mostly of cheaper origins like Chilean and South Africa There is nothing from Australia available.

I don’t enjoy shoju at all, but quite like the fermented rice wine called makoli and the local beer, but I feel that there might be an occasion when there will be an opportunity to share some claret in the coming evenings together. It turns out that I’m spot on with this decision. The bottle doesn’t go very far when shared 9 ways!

The first day of brick laying, with many helpers goes really fast and I lay out the parameters for the design and using a string line and plumb bob weight, I make sure that the chimney will be directly below the roof opening. This laying out is the slowest part of kiln building. Getting everything square and level before we start.

Many hands make light work and we lay the two floor layers in record time. I introduce these Korean professional kiln builders to ‘herring bone’ pattern floor bricklaying technique. They don’t seem to recognise what I’m doing, but using my phone and a translation app, I explain it to them as best that I can, and one of them googles/navers it and announces that it is called herring bone, and they all nod approval, discussing it in detail in Korean chatter as we work. This pattern helps to avoid any straight through cracks developing from left to right or front to back as the kiln shifts and moves as it expands and contracts during its firings.

2 days later, I notice that they have decided to use it in the base pattern of brickwork of their kiln foundations as well!

I get this unexpected extra manpower help with my brickwork, as the slab for the big kiln next door is not yet cast. In fact, the local builders are still relocating soil for the earth ramp of the man-made slope and then framing the formwork for the slab. Unbelievably, they get the freshly tamped earth roughly level and tamped down, then all framed-up with formwork and the cement cast by late in the afternoon. I’m pretty amazed by this fast work. However, I do notice that there is no steel mesh used in the slabs, and with it cast on top of freshly placed earth substrate, Will it crack in due course? I have no idea, but hope for the best. These Korean workers sure are fast. Going on this, I can only suppose that there is no steel in my slab either.

I am working flat out, as fast as I can to lay down bricks in their final positions to be laid with mortar seconds later, by one of my several helpers. They are professionals and are so quick. I’m hoping that I don’t make any mistakes working at this speed, as there is no room for any error. It gets particularly stressful when I have to lay out all the mouse holes and tertiary air inlets in under the floor and in the first layer of the walls. They need to be precisely positioned to work effectively, and I have no time to second guess if they are exactly right or not. working with four bricklayers calling for bricks keeps me thinking of four different parts of the kiln at once. Mouse holes, stoke holes, tertiary air inlets, flue holes and the door openings are all required in this first layer, and all at the same time. I’m used to working at a much slower pace and thinking everything through thoroughly. There is no time to think here at this speed. Luckily, I’ve done this before a time or two, so everything goes well.

By the end of the second day, we have the walls well and truely started and up a few courses. I have the luxury of having two of these enthusiastic helpers dedicated to using both of the diamond saws, cutting the hard fire bricks to special sizes to facilities the special openings that I need for the tertiary air inlets. These guys have never seen a kiln like this one with so many holes in it. Traditional wood kilns here are very basic in their construction, often, just straight through tunnels, or multiple chambers, one after the other with only the flue holes to think about. They keep asking me how it will all work, and I am at a loss to be able to explain the intricacies of the design to them with my limited Korean and just some charades to do the explaining. It will have to wait until dinner time, when I can get out my lap top and show them some images of finished examples. Everyone here has a phone with a translation app. I’m constantly turning round to face a phone screen to talk into, to give yet another explanation of a detail in the brick laying pattern.

I briefly have these 7 blokes on my team, and there is just one bloke stripping the form work and measuring the step dimensions and figuring out the layout for the big North Korean designed kiln next door. The cement slab is still fresh, soft and still very wet.

The next day, They are all going flat out on the big kiln, sorting out the necessary steps up the slope and making sure that the first layers will match the brick dimensions needed to align with the next step of brickwork. It’s a massive job. The kiln will have 5 chambers and a huge firebox with two arched openings at the front. They waste no time, and with 8 skilled workers the job flies up.

I am left to work on slowly on my small kiln, with occasional help from one of the bigger kiln team and someone to cart bricks and cut special shapes on the diamond saw when necessary. We work well together, and there is a lot of laughter, good natured banter and good will towards me. At the end of each work session, there are more questions about how it will work. I suspect that they think that I’m a bit mad, or at least quite quirky, expecting the fire to burn up-side-down and not roast my head off as a soon as I open the stoke-hole lid in the top of the fire box. Fire always burns upwards in their experience.

None of them has read my book on downdraught fire box kilns that The Director here of the Research centre has had translated into Korean about 5 or 6 years ago. Not a big seller apparently, among the traditional wood kiln building community?

I ask Mr Jung, The Director of the Porcelain Museum and Research Centre, to bring a copy of the book over to the kiln site, the next time that he visits, he does and it is passed around at morning tea time. A couple of the guys flip through the pages, but I don’t think that any one actually reads it in any detail. After dinner, I get out my lap top and show them images of other projects like this one to help explain what I’m try to achieve.

I build an arch formwork and set it in place on a stack of firebricks, using hand cut special wooden wedges that I place on top to adjust the formwork to the exact level needed, and also to allow me to pull them out and drop the wooden form work down free of the finished brick arch, to allow me to slide the formwork out of the chamber. This excites a little bit of interest in a couple of the bigger team, as they don’t appear to have ever seen this before.

I have read in older books, perhaps Leach’s Potters Book? That they just leave the form work in place in the big oriental kilns and burn it out later, before the first firing. I though that this was a bit wastefull. So I have never done this, always removing the formwork to be used again in another kiln in the future. When I tap out the wedges and drop the form work, there is a little intake of breath and a smile from Mr Kim who is assisting me at the time. He smiles broadly and taps me on the shoulder, thumbs up. He’s impressed. word spreads and my position in the social order rises slightly. At dinner, some one asks me how old I am. I tell them I’m 72, nodding all round. From this time onwards, I’m always ushered through doorways first and given the front seat in the car when we go somewhere. I’m accepted as one of them as a professional kiln builder, but I’m also the oldest member of the team. So as such I garner a little bit of extra respect as well.

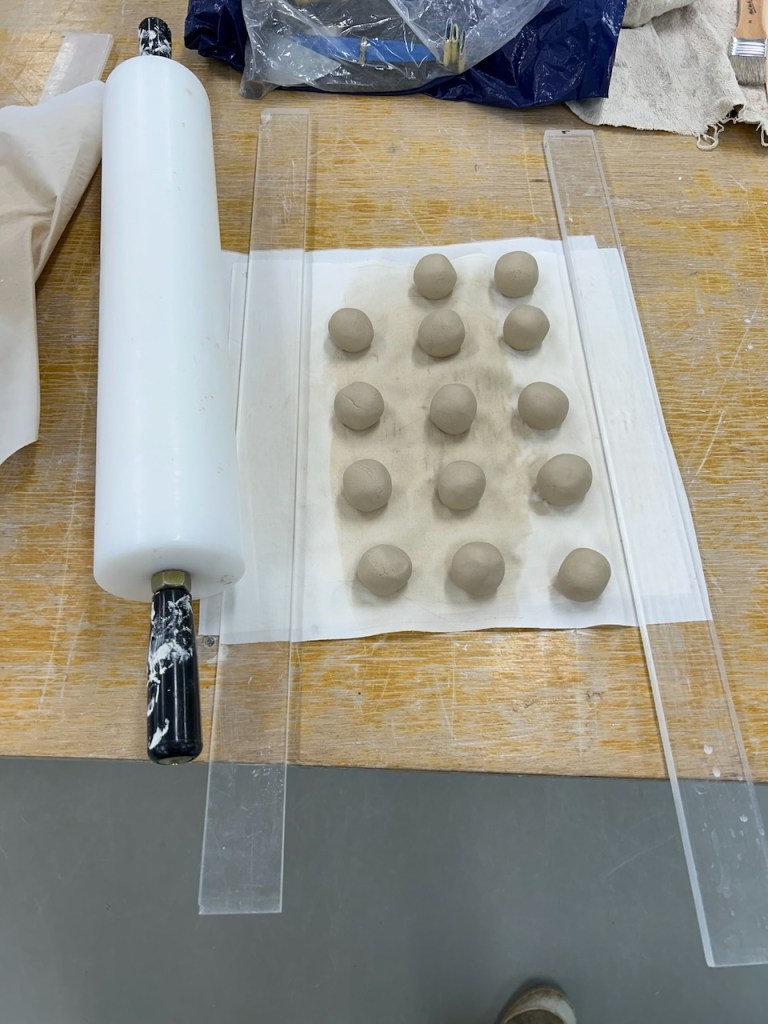

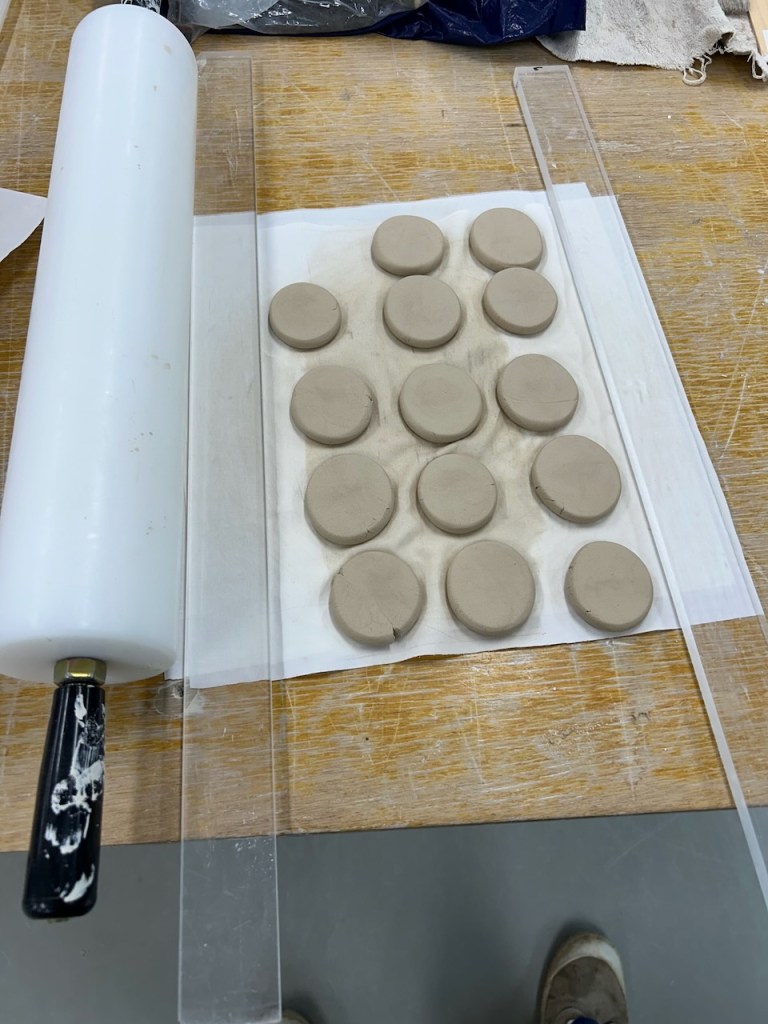

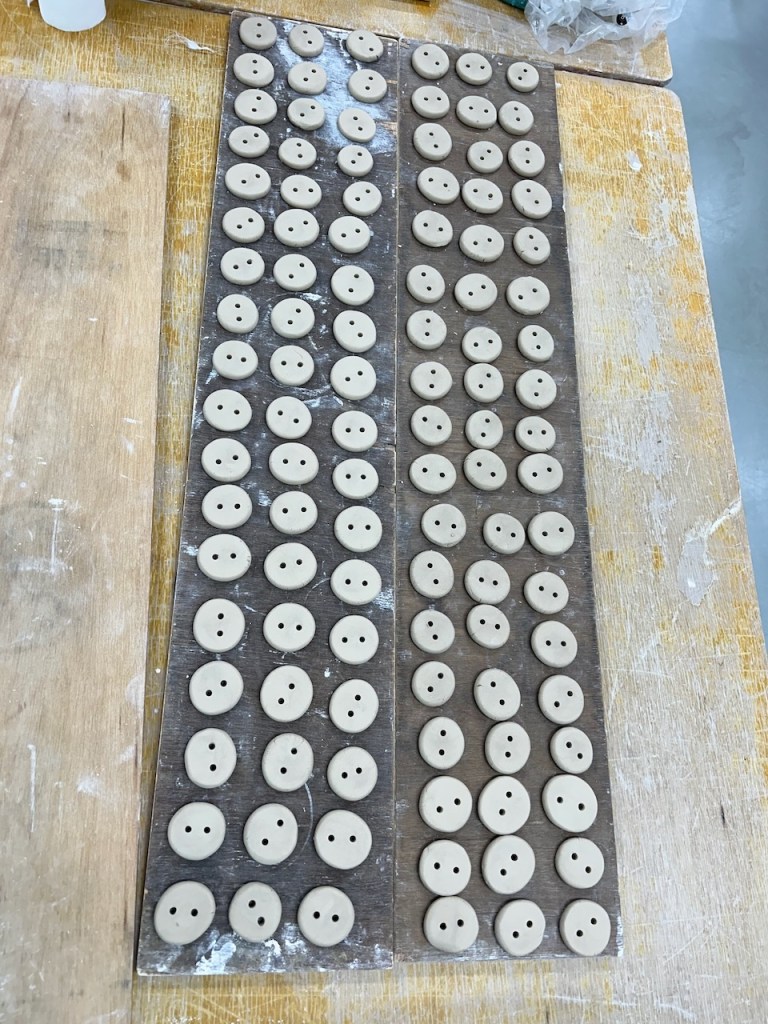

I finish the brickwork on my kiln by the end of the week and start to engage with all the multitude of little jobs that are needed to complete the kiln. I need make a load of ceramic buttons to attach the ceramic fibre insulation to the firebox lids. I also need to get a local company to cut and fold some thin stainless steel sheet to make the fire box lids.

I ask to be given a lift into the bigger nearby town of Yanggu, to buy steel angle iron and round bar to weld on the bracing. It all goes pretty smoothly, and in a couple of days the kiln is all braced in steel. Using a little portable stick welder I slowly work my way around the kiln, cutting and fitting the pieces together. I haven’t used a stick welder for 20 years. I’m a bit rusty on it, but it soon comes back to me. I’ve only used much more modern MIG and TIG welders in my kiln business for the past couple of decades. I have been spoilt by their speed and convenience, but I manage.

In some miraculous way, I manage to weld the 10mm dia. steel rod handles onto the 0.8mm. thick, or should I say thin, stainless steel sheet lids, using the little stick welder. This isn’t normally possible. The heat needed to melt the 10mm steel handle, is far too hot for the thin sheet and would normally burn a hole clean through the thin sheet. I’m aware of this, so prefabricate a small piece of angle iron backing plate that I clamp inside the lid to absorb most of this excess heat. I do burn a couple of small holes through here and there, but mostly it works well and I get the impossible done before lunch. More kudos from the pros on site.

They are treating me as an equal. It’s turning out to be a very good job.

You must be logged in to post a comment.