Exactly 8 weeks ago today, Janine and I harvested all of our apples and pears. We juiced them and used ‘Moet and Chandon’ champagne yeast to ferment them all into cider.

Now, 8 weeks on, the ferment has completely died down and used up all the available sugary nutrient in the juice. Now that it is completely still, it is safe to bottle it. We must make sure that it is fully fermented out, so that it wont keep on fermenting and explode the bottles.

I remember back in my childhood in the 60’s, stories of exploding ginger beer bottles that had too much sugar in them.

We have been making our own cider here for almost 50 years now, ever since we planted our first orchard and got a reasonable crop of apples.

This is our first vintage of cider in ten years now, because the orchard was burnt out in the big bush fires of 2019, but before that, there was a ten year draught that made it very hard to keep the fruit tress alive , never mind getting a good crop off any of them.

So this is our first really good cropping year from the newly planted fruit trees in the new orchard five years on.See; It’s almost autumn, Time to make cider.Posted on

I have just spent two days hand weeding and digging over the pottery verandah garden bed. It had gone completely feral and needed a good sorting out. All of the spring and summer flower display was mostly over and I’m hoping that all those flowers dropped a load of seeds down into the bed, so that now, given a bit of free space and sunlight, they will germinate and grow a new generation of flowers to welcome visitors along the driveway past the new pottery. I spent a long time on my hands and knees, making sure that I got the majority of the couch grass and kikuyu runners out of the soil.

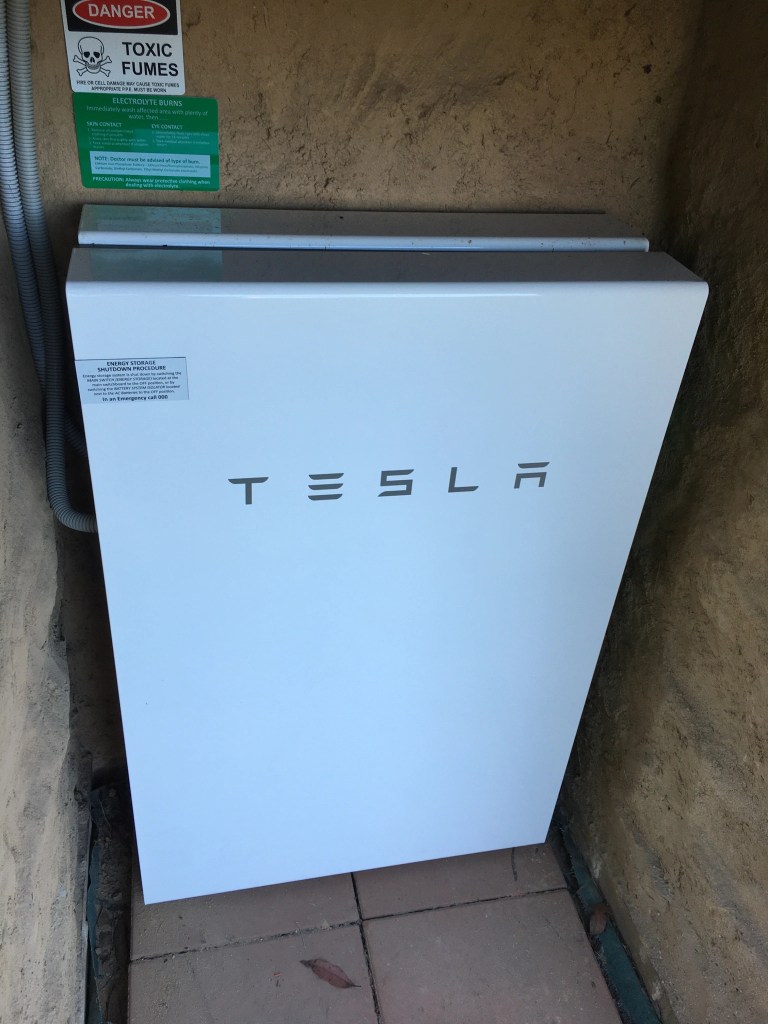

To prevent the grass runners from returning and growing back into the freshly weeded soil. I needed to make a border edging along the beds. In the vegetable garden, I made galvanised iron sheeting edging strips from off-cuts of galvanised flat plate that were left over from kiln jobs in the past. A very productive re-use of what was waste material.

These days I don’t have off-cuts any more, but Janine reminded me that I had stacked up half a dozen lengths of old recycled roofing iron ridge capping that might be usable.

I got stuck in and flattened it all, split it in two long lengths, and then folded a strengthening right angle edge on one side so that i could bury it half way into the soil to delineate the garden bed, but most importantly to cut off access to the grass runners from growing back into the beds. I dug in a ute load of compost, watered it well in, so now will wait to see what germinates.

Re-use, re-cycle, re-purpose!

One of our cherry trees has decided to flower again in autumn. I think that it had a few cold nights, followed now with some warm weather, and that was sufficient to reset the biological clock thinking that winter is over and time for the spring flowering. We have had this sort of thing happen in the past. Particularly with the ‘low-chill’ cultivars.

Winter hasn’t arrived yet, so I wonder if this tree will still flower as normal in 4 months time when spring does actually arrive?

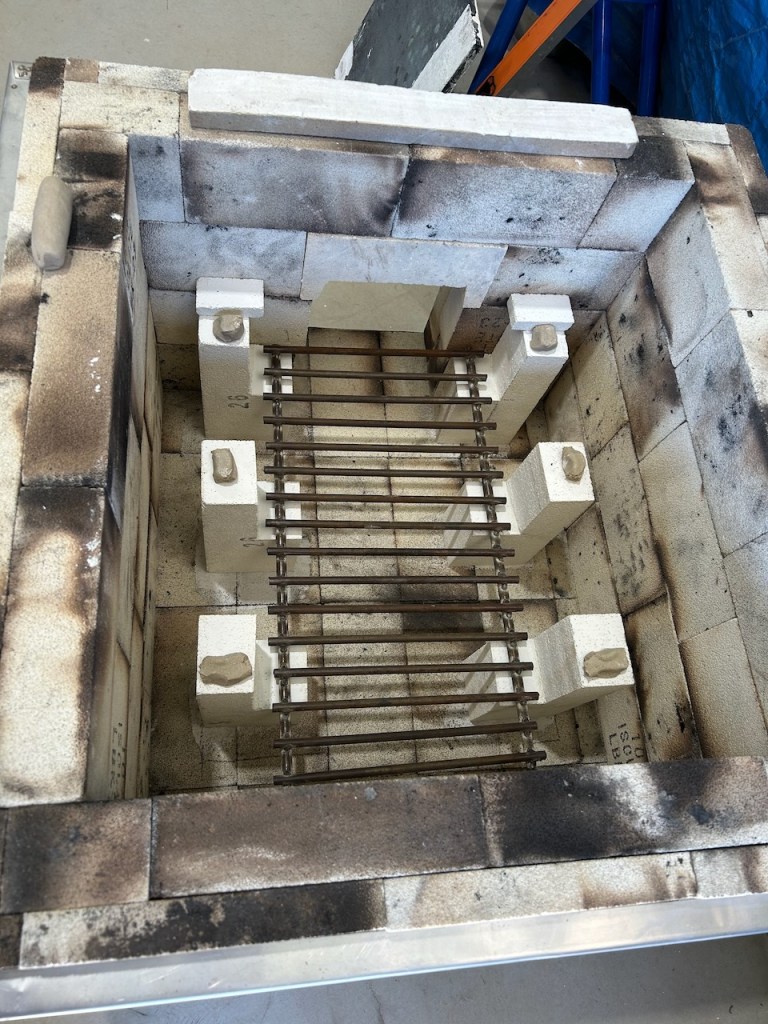

In the pottery, I have retested the rock glaze tests that i started exploring a few weeks back. This time, I have made larger sized samples to see the quality of the glazes better. All 3 have potential, but still need further testing to get them ‘right’.

After washing and sterilising all the glass bottles for the cider bottling this morning. I had and hour to wait for the sterilising process to complete, and could hear the birds in the lillypilly tree next to the house. I asked Janine if she wanted to make some lillypilly jelly, so got out the 3 metre step ladder and climbed up into the canopy to fill a bucket with fruit. The fruit only starts 4 to 5 .metres off the ground. The tree is much taller then the house.

After we had bottled all the cider, Janine boiled up the berries and started the process of making the jelly. It takes two days. Tomorrow to sieve out the skins and stones from this batch, then re-boil it and set it up in a cheese cloth to drip out to clear jelly.

Nothing is ever finished, nothing is perfect and nothing lasts.

You must be logged in to post a comment.