We have been creating a life here for over 40 years, living as much possible as off our few acres of forrest, orchards and gardens. We have spent a lot of personal energy in converting all our energy needs, to wood fired everything. We have chosen to leave half of our land as forest, and there are always trees that are maturing, dying and falling over in that forest.

We haven’t harvested all the trees that have fallen on our land, as there are too many, so we have left the ones in the most remote locations to rot, as it was just too much effort to make a track into the bush to get to them out. If a tree falls in the forrest – does anybody hear? No! That is line from a song. If a tree falls and we let it rot, then it ends up the same as if we cut it up and burnt it in the house oven or kiln. The carbon that was taken from the air and soil, returns to the air and soil, only just a bit slower with composting than burning it in the kiln. Composting is a slow form of combustion.

Having spent a lot of thought and energy converting our life over to non-fossil fuel energy, we now find that with global warming, the fire bans start a month earlier and go on for a whole month or more longer in the autumn. This has caused us some trouble lately, as we have had to cancel the last few, late winter/early spring wood firing workshops here in the past couple of years.

So, if this new warmer future is to be our new reality, we had better make plans to adapt. Well we have. Starting 13 years ago we decided to go fully solar on our house and workshop and haven’t paid an electricity bill since. Those early Australian made solar PV panels have now paid for themselves, and from now-on we will have free electricity for the rest of our lives.

We live so frugally in our home these days, that we have found that we can now live on a quarter of the electricity that we used to. We have done this very simply by introducing efficiencies. As old appliances wore out, we replaced them with very low energy newer models. It’s not hard to do, but it takes time and a lot of research. It has taken time because we didn’t just throw out working appliances. We waited until they died of old age. There is so much embedded energy in electrical goods, that it is a crime to replace them before they are worn out. We have reduced our daily energy consumption in the house from 11 kW/hrs per day down to 2.5 kW/hrs. This means that there is now a lot of excess, clean, solar electricity that we can use to fire our kilns cleanly and efficiently.

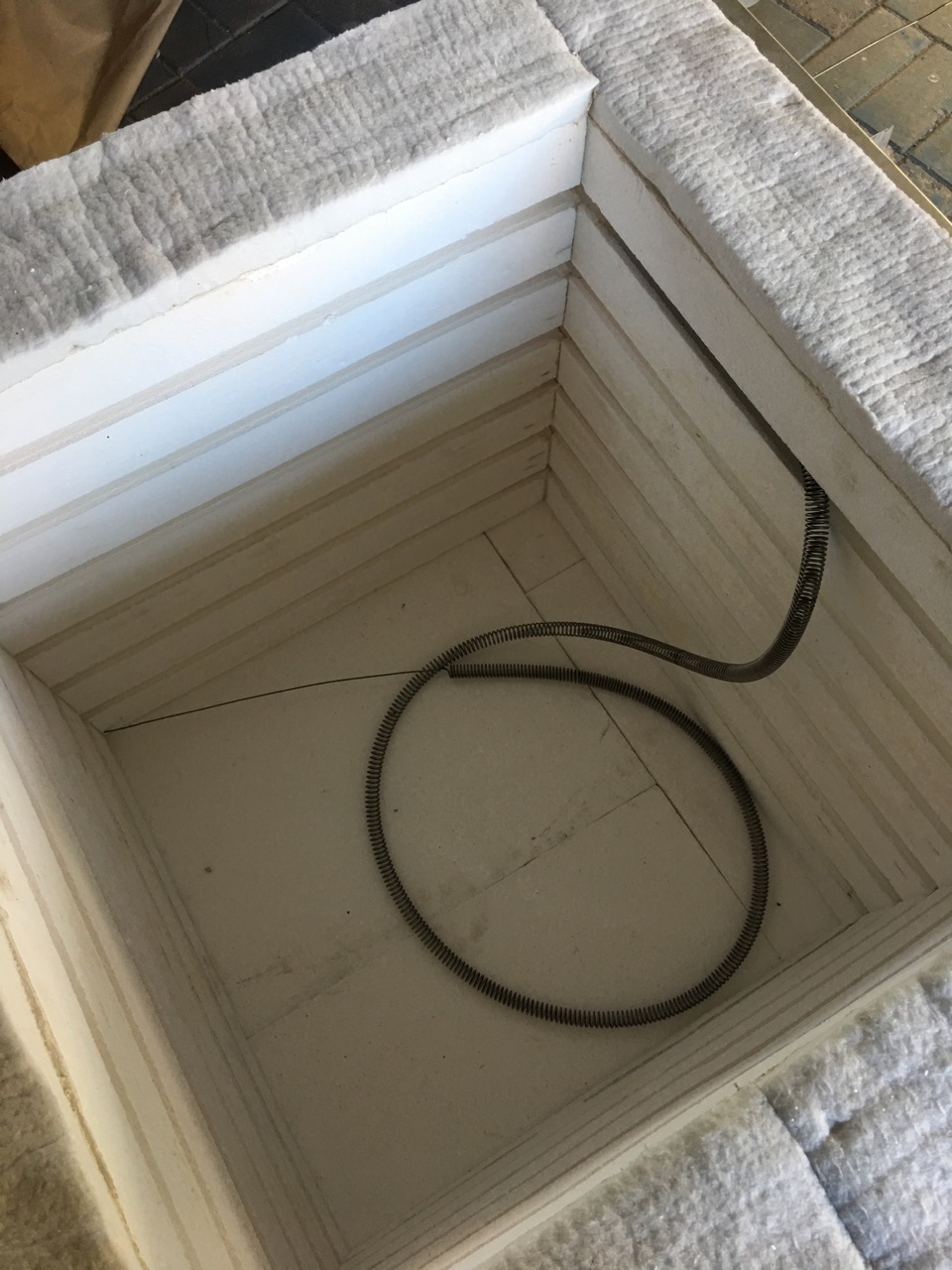

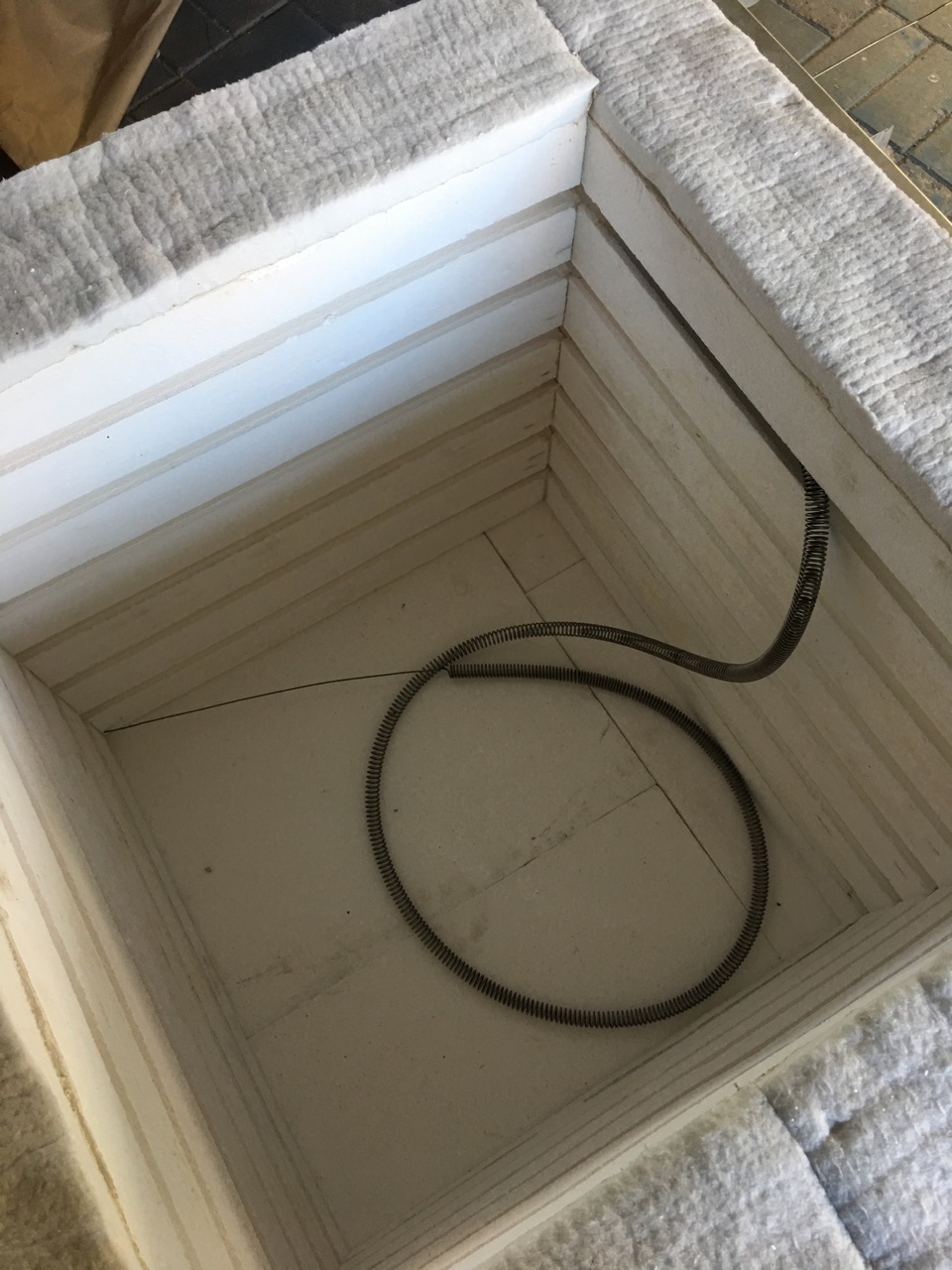

As we now have a problem with firing the wood kilns all year. I have decided to convert all our Electric firing over to solar PV. I have built a new light weight, portable electric kiln from very low thermal mass materials. I have included a couple of small LP gas pilot burners into the design, to allow me to create reduction atmospheres after 1000oC with tiny amounts of LP gas while the solar panels and the battery fire the kiln load of pots up to Stoneware.

There is nothing earth shattering about this. Korean, Japanese, and Chinese potters that I have met and worked with have been using a combination of LP gas or wood fired electric kilns for years.

This is my version of the idea. Light, flexible, portable, low energy and suitable for solar PV and battery firing.

It didn’t hurt that I was able to build it totally from spare parts and waste material that was left over from my many years as a kiln builder. I only had to buy a thermocouple for this kiln, as the old-fashioned temperature controller unit that I had sitting in a box for the past 20 years, needed a specific thermocouple to make it work.

I find it amazing and very rewarding to be able to convert a few boxes of old ‘rubbish’ that other people had thrown out, plus some left over material, and turn it into an amazing, functional, energy-efficient, working kiln.

I had a couple of sheets of stainless steel left over from other jobs.

I have been storring a few sheets of ceramic fiber for over fifteen years. They are left over from a glass kiln job that I did many, many years ago. They are pre-fired, pre-shrunk, hardened and ready to use for a job just like this

I even find that I have a shrink-wrappped coil of Kanthal A1, element wire sitting in my store. It’s been there for years. It was left over from a job that I tended for, but which never materialised. I spend sever days working on these new heat flow and emisivity calculations to get the best answer for what I have in stock, compared to what I really want to achieve. After 5 goes at the problem, I have generated many pages of mathsand enough energy to warm the kitchen when I’m working and re-working out all the perameters. I eventually get a good answer that I can live with. I have to make a new mandrel for my lathe to suit this job. I find that I can use some of the left-over stainless steel fire-bar material that I still have from the little portable wood fired kilns jobs of the last few years. It turns out to be just about the exact size that I need. I alter my calculations and go ahead and use it.

When I go looking, I even find that I have a few control pyrometers and a couple of infinity switches to do the basic job of controlling the kiln. It’s not an electronic, solid state, ramp controller, but it will do nicely. I will have to do the first few firings in conjunction with pyrometric cones viewed from the small circular spy hole.

After a few weeks of part-time work, fiddling away in my spare time. I have what I think might be a functional kiln. I have sifted through several piles of ancient junk, destined for the re-cyclers. I have discovered a lot of functional bits and parts that I wasn’t very interested in using 20 years ago, but which I can see potential in now. So many potters wanted to have their kilns converted to electronic ramp controllers in the past. I did the conversions for them, but couldn’t bring myself to throw out a perfectly good, working order, analogue kiln control unit. I’m now glad that I persevered, and storred all this junk for so many years.

I’ve found that I have enough parts to build two kilns, so I probably will. This first kiln is designed to be very low thermal mass, firing to stoneware on solar PV + with some back-up later in the day, as the sun goes down, from our Tesla Battery. I have a couple of very old, but un-used, brand new, pilot burners, these are so old that the company that built them has now ceased to exist. My plan is to use these two tiny pilot burners to create just enough CO atmosphere to give me adequate reduction, while the elements powered by the solar PV fire the kiln.

I’m hoping that it will work as I planned. Only time will tell. Watch this space.

It’s been quite good slowly fading into semi-retirement. Cleaning out years of old boxes that I had forgotten about on that dusty top shelf. There were two whole kilns stored away in the form of spare parts.

You must be logged in to post a comment.