We have just harvested the first cabbage and first broccoli of the autumn. I planted a range of brassica seeds on boxing day. The first batch were all dug out by the blackbirds, so when I re-planted the 2nd sowing, some time later. I also covered the bed with bird netting to stop a repeat of the blackbirds scratching out the seeds. Blackbirds don’t want the seeds, they just like to scratch into freshly worked and composted soil looking for worms. This little hiccup set me back a few weeks, so our first cabbage is a bit late arriving.

I have now repaired all the melted sections of the plastic netting over the vegetable garden. Almost total replacement at both ends that were worst hit by the fire, then applying patches to the large holes in the other walls, and finally stitching together the small 50mm to 100mm holes that are scattered all over the enclosure walls and roof. I purchased a commercial size roll of 100metres by 10 metres of netting over 30 years ago to cover the vineyard at harvest time. The netting that is over the veggie garden now is all that is left over from that time. It had a 10 years warranty against going brittle with the ultra violet light. So I’m very pleased that it has lasted so long. However, it is getting very brittle and the galvanised steel netting is all rusted through in places. So a total rebuild is in order, but I’m not too sure that I can manage that big a job these days, or if it would even be wise to attempt it at my age, having just turned 73, I shouldn’t be up and down ladders for days on end.

I made an Australian version of oka-nomiyaki pancake. Of course it is not really an okonomiyaki, as I don’t have mountain-potato starch, or almost any other authentic Japanese ingredients, but I do the best that I can with what I have. The super-fresh garden ripe cabbage makes it really fresh, crisp and delicious. The broccoli goes into a veggie stir fry along with all the other garden delights of the current season and some tofu for protein. Vegetable gardening, which mostly involves a lot of weeding, mowing and watering, suddenly becomes so worthwhile when you are harvesting such beautiful produce each afternoon, freshly picked ready for dinner. Our food has carbon metres, not miles!

I have also planted another 4 different varieties of seed garlic in the garden, just to see if any of therm are well adapted to grow here in the future.

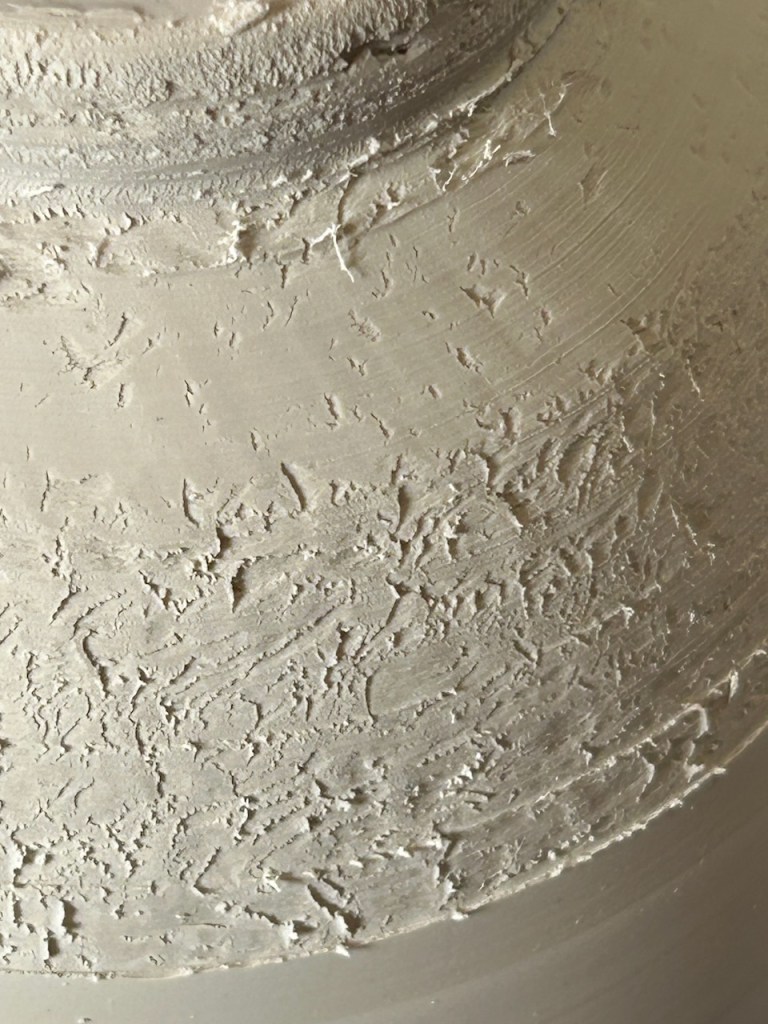

In the pottery, I have been throwing some sericite porcelain stone bodies. This stuff is so short that I have to make the wall bases thick to hold the form up. That then means a lot of turning to get the pot thinner again. This weird stuff tears and rips as the turning tool cuts into it – unless it is turned quite firm and almost dry. But then there is the dust to contend with, so I like to do it while it is still a bit damp, but then it chips a lot. It becomes a two stage process. Roughing out the mass of extra thickness, drying some more, then final turning. I get to do a lot of slaking and re-cycling of turnings.

I have built an extra-large tray for my shimpo, but with this porcelain, I still fill it very quickly. This image is of the trimmings from just 15 small 150mm. bowls.

It all goes into the mixer pug and is recycled, ready for throwing again the next day, although leaving it to age a little bit and ‘recover’ would be even better, but because I use a dozen different mixtures and recipes, it is easy to loose track, with too many small packs of different clays hanging around. So I prefer to use up each batch all in one go as soon as possible.

The tyre on the old wheel barrow went flat last week. I took it to the tyre place to get a patch or a new inner tube, but they told me that the tyre wasn’t worth working on and I’d need a new tyre and a new inner tube – at a cost of $78! As the old metal rim is quite rusty, I decided that I might just as well buy a whole new wheel unit from the big hardware chain for $32! But then I remembered that I had a complete wheel off a buggered trolly that I picked up off the side of the road on council clean-up day. It is 25mm smaller in dia. but still holds air pressure well, so I had to change the shaft size and make some new brackets to hold it on, out of scrap tin plate. 20 mins later we are all back in business and good to go. It’s not perfect, but it works. Recycle, reuse, repurpose!

The Japanese have a word ‘Mottainai’ – too good to waste!

A botched up job that will keep all of this useful material out of the waste stream and land fill for another decade. I actually picked this whole wheel barrow up off the side of the road in the village some years ago on Council clean-up day, when the owner decided that it was just junk, because the tyre was flat. I took it home and just pumped it up. It worked! And has been working hard here for all those years of reprieve since then – and now still continues to be useful. Waste averted, Mottainai!

Nothing is ever finished, nothing is perfect and nothing lasts.

You must be logged in to post a comment.