K-pot Journal

There is a world-wide phenomenon in international popular music that has taken the world by storm in the past decade or so called K-pop. A style of popular Korean music, loosely based on traditional Korean music styles, but greatly influenced by loads of Western music styles like hip hop, R&B, rock, jazz, even gospel, reggae, electronic dance, folk, country, disco, and classical. Every body seems to know about K-pop, this Korean cultural export.

I don’t know much about K-pop and Korean popular music, I come here to study ceramics, so I thought that I’d call this blog K-pot! On my first visit to Korea, 8 years ago, I wrote a blog called ‘The Kim-chi Chronicles’ (Sept 2016), This blog is its latest incarnation.

This is my 7th visit to Korea, since I first came here in 2016. I was here only 6 months ago for a ceramics conference, where I presented a paper on low emissions wood firing. This involves using a kiln with a downdraught firebox (Bourry box) which is capable of firing with relatively little smoke. Of course there is always some smoke when burning wood, but this style of kiln design keeps it to a minimum most of the time.

In Australia, where I have done most of my research, I use hard wood, eucalyptus trees for fuel. Eucalypt hard woods are heavy and dense. They burn slowly and steadily. Perfect conditions for low smoke emissions. Here in Korea, they have a lot of different softwoods in the form of pine trees/conifers. They burn fast and furiously, so it is a challenge to minimise smoke during firings.

People here have asked me what is the secret addition that you have incorporated into the kiln? As if there is some sort of afterburner, that they can add to their own kiln to clean it up. There is no secret addition! It is a complete kiln design incorporating the virtues of the down draught firebox that burns the wood more or less in stages, so that there is no intense emission of volatiles that causes smoke in most other kilns.

So I am here again in Bangsan, in the Yanggu Porcelain Village, this time not as an artist-in-residence, as I have been in the past, but as a kiln building tradesman, a glorified refractory bricklayer. I have been tasked with the job of building a small kiln here that demonstrates that wood burning kilns can be fired with a minimum of smoke.

This project was first floated way back in 2018, when the director of the Yanggu Porcelain Museum and Research Centre, Mr Jung Do-Sub, asked me if I would be interested in such a project. The Museum had purchased the rights to publish my book, Laid Back Wood Firing, and had it translated into Korean. They have also published my other books ‘5 Stones’, and ‘Rock Glazes, Geology and Mineral Processing for potters’.

Unfortunately, The translator took someone else’s advice and renamed the book “Smokeless Wood Firing”. Which is of course not true. all wood creates some smoke when being burnt. My project is to keep the smoke to a minimum. Calling the book ‘smokeless woodfiring’ only creates false expectations, and room for criticism and disappointment.

As a result of the books’ publication, there was some interest in getting one of my kilns built at the Yanggu Research Centre as a demonstration model. Like other places in the world, There is a growing interest in cleaning up the environment, at least from the grass roots level, not from there polluting industries, who are being dragged kicking and screaming to be made to be kept to account. It is this citizen-lead interest that is putting pressure on political leaders to make some sort of gesture to seem to be doing something, while still taking large donations from the polluters to keep the status quo.

The result is a very slow transition to clean up the environment. The results can be seen here in this tiny, remote village. When we were last here before ‘Covid’, in early 2019. The streets were being dug up and gas pipe lines being installed to every home and business. Previously, most home heating and commercial cookery was being done using pressed coal briquettes. Dirty, inefficient and polluting. The immediate result is much cleaner air.

These days the smoke from the wood fired kilns looks just as polluting, now that the residents have paid to have cleaner gas installed, to eliminate their smoke, why shouldn’t the residents want cleaner air, and less smoke pollution from every source? The traditional kilns here are very smokey, producing black smoke all the way through the firing schedule, from start to finish, particularly at the end of the firing, when the extra chambers of the climbing kilns are being fired by ‘side stoking’ methods.

There are two climbing kilns here in the centre of the village behind the research Centre and Museum. One of them right next to an ancient kiln site, where porcelain has been made since the beginnings of porcelain making here, hundreds of years ago. With an ancient tradition of pottery making here in the village, using these old kilns going back many hundreds of years, it’s hard to suddenly say NO! Just stop doing it. So the Director of the Museum, was thinking a decade in advance of this possible occurrence.

He managed to secure access to an abandoned military base, a few kilometres out of town, up a small valley, well out of the village, where a new

Smoke from one of the traditional kilns here.

‘Porcelain Village’ is being built. When I first arrived here 8 years ago, in this new development, the buildings were still very new and my room still smelt of fresh paint, and all the facilities were still being installed in what had been the officers quarters. One of the stone barracks was being converted to a meeting room and coffee shop. The Museum director had big plans to build several different styles of kilns out here to add to the research facilities available to the students. That has since then, mostly all come to pass. However, the plan keeps changing and expanding and getting more complex.

The Museum Director is a very smart guy, a good strategic thinker and politically very savvy.

The first kiln built up in the valley was a tunnel kiln. I didn’t see this kiln being built, as I have been away for 5 years because of the COVID lockdown, and then the huge catastrophic bush fires that burnt our pottery. It has taken me 5 years to recover, so that I could finally accept Mr Jung’s offer to come and build them one of my kilns.

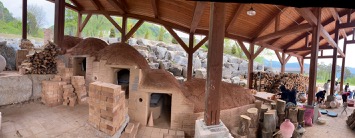

The second kiln built here was a traditional low-firing, earthenware wood kiln, the design of which, originated in Jeju Island off the far South Coast of Korea. It is built out of basalt stones. The only available material on Jeju Island, so is limited to very low firing temperatures. A kind of tough earthenware.

Hand made fire bricks stacked to dry in front of the Jeju basalt stones kiln

The third kiln built here was a traditional 5 chambered climbing kiln, built almost entirely out of hand made blocks and bricks for the walls, and hand rolled cones of local fire clay for the dome and arches.

Hand made clay cone shaped bricks set out to dry in the kiln shed.

The 5 chamber domed climbing kiln getting ready for its first firing

There are 3 independent, self contained workshop/residencies for artists and their families, and another building with 4 bedrooms and 4 studios, suitable for single student residents. Each of the studios has it’s own electric kin and pug mill. There is a huge communal clay processing and kiln firing building with 2 large gas kilns, and finally a very large conference/residence building that can sleep up to a dozen people with large multiple bathroom, toilets, and even a sauna and laundry.

As far as I can ascertain, all the residents/students here have already completed MA hons degrees from their university, and have come here to study for up to 5 years to gain their PhD in porcelain research. It appears that they get rent free access to all the facilities here and only have to pay for their gas and electricity bills. An amazing deal. Such great support for the Arts here! In exchange, they are expected to take part in communal activities like the making of the hand made fire bricks for the last kiln built here. or making the years supply of small test tiles for glaze testing.

There are plans for the local government to develop and sell off several privately owned and developed house and pottery studio sites, next to the research facilities. There may be up to 8 or 10 of these house sites. 2 of them have now been taken up, and buildings are currently underway. It will become a small porcelain village and creative community.

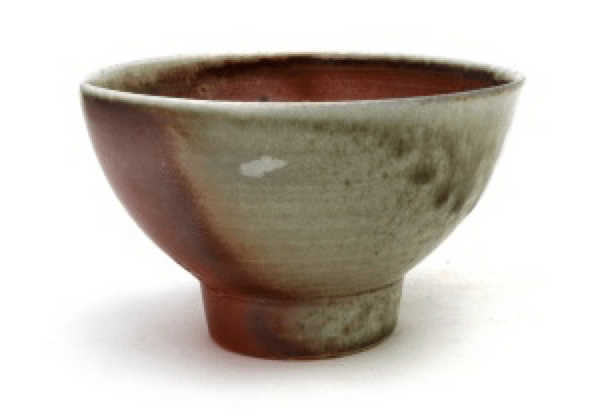

My wood fired kiln is small compared to the vast climbing kilns here. But it is actually quite a large kiln of 85 cu. ft. or 2.5 cu. m. Very large for a single potter to fill regularly in Australia. However, I expect that it will be filled by group effort here, just like all the other big kilns. Mine will be the 5th wood kiln to be built on site here. A demonstration model of what might be possible in terms of reducing smoke pollution in wood firing, while still achieving reduced stoneware wood ash effects.

I only hope that it all goes to plan, However, I am mentally prepared to accept some smoke, as all the wood here is very dry pine, that will burn intensely, so I will have my work cut out to get a good clean result. I will be severely embarrassed if it all ends up going pear shaped in the firing. So far the kiln looks good and is built to the specifications that I usually rely on when designing similar wood kilns. But knows what will happen when I fire it with very dry pine fuel. I can only guess, but I imagine that there will be some smoke.

My finished kiln with 2 Bourry style downdraft fire boxes side by side.

Ready for K-pot firing. I have to wait and see what my decisions were like.

You must be logged in to post a comment.