Warning! This post might be very boring!

Don’t read on unless you want to learn something about clay.

Janine and I have been teaching weekend workshops these last couple of weeks, and all of the preparation that goes into that to make sure that everything runs smoothly keeps us very busy. The whole exercise takes us 5 weeks in total. However, there is still time for other fun things like the garden, chickens and cooking

Over the week in between the two weekend workshops, I re-cycled all the clay from failed and re-cycled practice pieces that had made their way into the clay room to be stiffened up in the plaster basins. I have 5 large plaster tubs sitting in the direct light of the North facing window, this keeps them dry and ready for use, most of the time. Plaster saturates quite quickly if thin slip is poured into them, but they cope very well with soft plastic slumped pots that just need stiffening up. 20 mins on each side on a dry plaster batt, is all they need and it’s well and truely ready to wedge up and use again.

At the end of the workshop, I get everyone to collect all the trimmings, turnings, scraped-off batt bases and thick slurry from their throwing water tub, and pour it all into a tall 20 litre bucket. 8 potters can fill it up pretty quickly. I let it sit and soak for a day or two, to make sure everything is equally softened, I like to get it to a thick and creamy consistency, not unlike Greek yoghurt – with some lumps.

I then transfer it all onto the plaster drying tubs. It takes 3 days to get stiff enough to lift it out and stand it up. This allows more air to circulate around the soft, barely plastic clay, so as to dry it out faster. The plaster basins then need a few days in the sun to dry out again. When we do back to back weekend workshops, the plaster does get saturated and ‘tired’! However, it always recovers with a few days of sunshine.

Once stiff enough, I put it back through the pug mill, extrude it and bag it ready for re-use. It’s easy mindless work. However, I say that in the full knowledge that it is only so if you already know exactly what you are doing and have done a lot of it before. There are so many little signs and issues that you need to know and be aware of to understand about pug mills and recycling clay. The joys and sorrows of owning a pug mill!

The clay can’t be either too soft or too hard, or the mechanism of the pug mill won’t work. A pug mill is in essence, a long tube with an Archimedes spiral inside. This spiral blade pushes the clay through the barrel. Some parts of the spiral at the beginning are removed to make the spiral into a series of spiralled chopping blades. This chops up the clay, mixing both hard and soft parts evenly, then the later, complete spiral section of the auger pushes and compresses the clay out the other end. Some of the better pug mills have a screen or screens half way along the barrel so that the clay is pushed through the mesh and comes out the other side as clay spaghetti. This exposes any trapped air bubbles which are then sucked out of the pug mill barrel by a vacuum pump, before the clay is recompressed and continues along the barrel.

There can’t be any little bone dry edges that have dried out too far. They are rock hard and dry and will clog up the vacuum screens. I have to constantly check when running my fingers through the thick slurry, that there are no small tools, profiles, kidney shapes, or chamois strips left behind by my students. Any of these will grind the exercise to a rapid halt. Requiring the pug mill to be stripped down, dismantled, cleaned, the offending ‘rubbish’ removed, then checked and rebuilt. It’s the best part of a full days job to to a thorough clean out. If it’s only a chamois, sometimes, I can get away with just removing the blocked vacuum screens, cleaning them only and reassembling. This is still a good hour or so.

In the picture above, the orange vertical plate on the side of the blue pug mill barrel, half way along the barrel is where the vacuum screens are located and can be removed for cleaning. The white lid on top of the barrel is where the vacuum chamber sucks out the air. The vacuum pump is located in a box slung underneath the pug mill trolley, which is on castors for easy manoeuvring.

So far, I’ve been very diligent in checking all the recycled clay pretty thoroughly, so I haven’t had any ‘accidental’ issues in the last few years. I did discover, quite early on that the new pottery shed, with its north orientated, solar passive design, does get a lot of direct sunlight in onto the clay processing area in mid winter. I’ve learn’t from hard experience that direct sunlight like this can cause the pug mill barrel to heat up and sweat moisture out of the clay on one side, which then condenses and trickles down to the bottom of the barrel. The end result is dry hard clay in one part and slurry in another. The dry, very stiff nuggets of hard clay get forced onto the fine mesh of the vacuum screens and clog it up. The rheological nature of the thin wet slurry in the other part of the barrel doesn’t have the cohesive strength to force the hard clay through. A complete strip down is required. This is a lesson that I learnt the hard way.

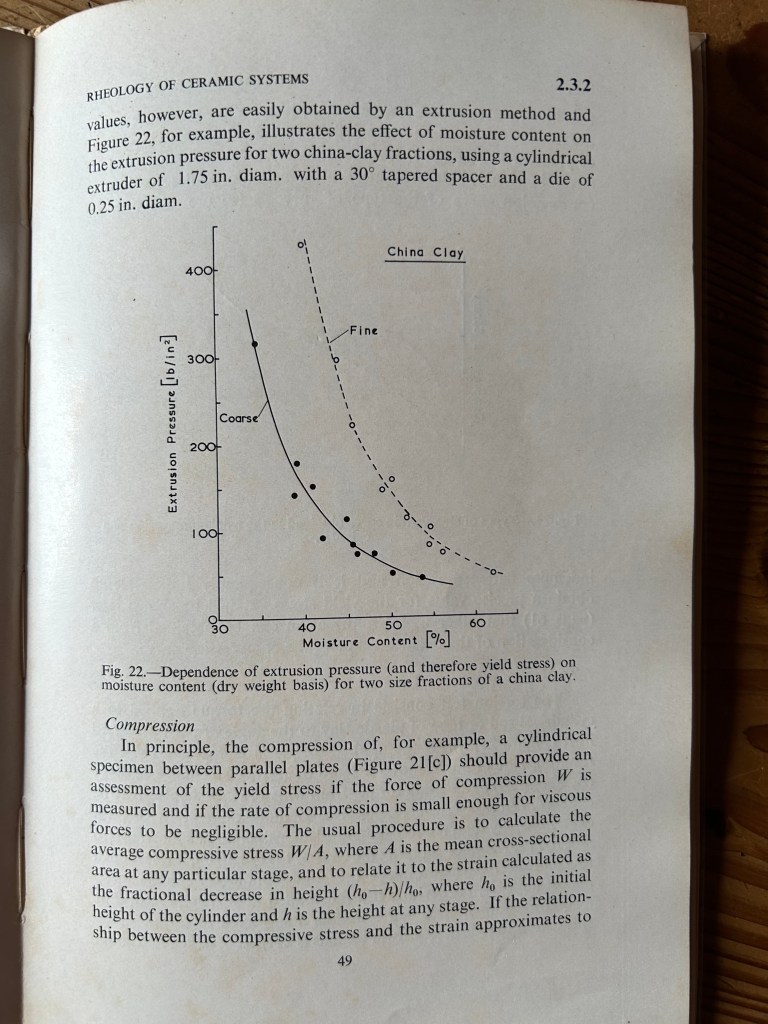

Rheology is a very interesting subject in itself. Clay can be either too soft or too hard to stick together and be ‘worked’ or shaped successfully. There are limits called ‘Atterberg’ limits that have been determined, which predict the upper and lower limits of water content in clay. If too wet, it just sloshes around and won’t hold a shape, when too dry, it is just crumbly granules. We need the ‘Goldie Locks’ range for our clays to ‘work’ successfully. For pressure extruding the range is somewhere between 17% and 60%,. That’s such a huge range. See graph. For pugging, it needs to be in a narrower range of 20% to 30%. depending on the inherent plasticity and texture of the clay body. For throwing clay on the potters wheel, it is often closer to 20 to 22%. I have found in practice over the decades that my wrists have their own personal Atterberg limit of around 25% water content or even a little bit softer rather than stiffer.

Some people say that you should work to your strengths. I think the opposite, I work to my weakest point, and as that is my ancient wrists. I have adjusted my clay body recipes over time to include more very fine plastic particles, slightly more course non-plastics and more fine sand. This combination allows me to make softer clay mixtures that are still easy to pug and easy to throw on the wheel when very soft. I am limited by what is still available on the market here. So many materials that we used to be able to get have been removed from the market, as the Australian companies that own clay mines were purchased by multinational players who shut them down to force us to buy their imported products.

Luckily, I was trained in the 60’s and 70’s when clay technology was still taught in Art School. I even went on to teach it myself for a few decades. So, I can develop and test my own clay body recipes. A skill soon to be completely lost, as us oldies retire and die out. I can still obtain Australian mined and milled ceramic materials from NSW, Vic and Qld, but the options are constantly diminishing. When I have been shown commercial plastic clay bodies over the years, I have always found them to be far too stiff for my wrists to feel comfortable with. Possibly because of a lifetime of damage due to hard work with my arms, wrists and hands?

So dry lumps of clay on the pug mill screens stops everything in it’s tracks, until the screens are removed and cleaned, and this can be a big job, depending on the maker and model of the pug mill. We are lucky here in Australia to have the ‘Venco’ company, who under the direction and vision of Geoff Hill, manufactured pottery equipment here since the 70’s. His version of ‘Harry Davis’s, genius design’ of vacuum pug mill was an excellent piece of machinery. The smaller, cheaper, models require that the entire machine be diss-assembled to get to the singular screen. However, the larger, and more expensive models are designed so that the screens are accessible from the outside of the barrel and can be accessed directly for cleaning.

So now I have learnt to keep my pug mills covered with silver insulation foil when not in use, and this has solved the condensation problem. There is always something new to learn, even after 50 years!

Once pugged and bagged, It’s not the end. Good clay that has been well made needs to be nurtured a little. Clay is alive, in the sense that it contains live microbes, or should if you want it to develop the best possible plasticity. We live in the bush here in Balmoral Village. There are few Government services. There is no Town Water Supply available. So we have to collect rain water in dams and water tanks. Water stored in the ground has more bacteria live organisms than Chlorinated and sterilised city water. My clean rain water will allow the naturally present bacteria and other organisms to grow and develop in the clay. This might sound shocking, but it is just natural. Clay ‘ages’ as the organic action develops between the clay mineral particles. The water is drawn closer to the surface of the fragments and the air is slowly excluded and passed to the surface by capillary attraction. In this slow gentle way, clay develops its full plasticity. It is very noticeable after say 3 months. But a year is better! Of course, no-one in their right mind would make clay and then not use it for 3 months! Would they??? Yes muggins does. I have stored and aged porcelain bodies up to 15 years.

There is a distinct difference in the clay after a period of ageing. Clay body made with chlorinated water inhibits the natural growth and ageing, so does not develop the same plasticity.

In the old pottery, there were a lot of eucalypts growing around the building, and consequently there were a lot of gum leaves in the rain water. These made the water a little acid with their tannin. It turns out that tannic water is just about the very best additive that you can put into clay to improve its plasticity. Our gum leaf infused tannic rain water was a pale, transparent grey/brown colour. Some fancy companies that manufacture commercial Porcelain bodies, buy in, at great expense, a product called ’Totannin’, that does much the same thing. Our clay really responds to any time left wrapped in plastic bags, sometimes double bagged, for long term storage. Then stored in a cool dark place and not touched for as long as you can bear it.

Each Friday evening, before the workshops, I bake a loaf of bread and a tart. This time, its beetroot and French goats cheese over a bed of slow cooked onion jam. This has always proved to be a very popular lunch contribution at the workshops. Every one brings something to share for lunch. There is always just a bit more than we need. Everyone eats well and the selection is broad, varied and delicious.

We spent the first day on the wheel, throwing all the forms that we will work with on the following day. I demonstrate each step in the process on each day.

Teaching a throwing school in winter is always just a little bit of a challenge. The pots don’t want to dry out over night to stiffen up to the point where they can be turned, trimmed, manipulated and handled with ease.. I get the pots to dry faster, by stoking up the slow combustion stove to the max, and keep it going well into the night, to ensure that the pots evaporate off enough of their moisture to be workable. It’s a juggling act, but I manage to muddle through, and at the end of the weekend, everybody gets to take home their finished works.

In the orchard, the early peaches and nectarines are flowering. There is only 3 more weeks to spring, and lots of plants are starting to come back to life, buds are swelling and even the lawn is starting to grown again. This last part isn’t so thrilling though, as this means a few hours of lawn mowing several times a week.

Spring blossom always offers up so much positive energy, the a promise of warmer weather and a bountiful harvest to come.

Nothing is ever finished, Nothing is ever perfect and nothing lasts.

Enjoy the moment.

You must be logged in to post a comment.